Advantages

The main advantages are:

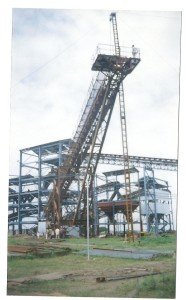

- Saving in construction time: About 30-50% saving in total project schedule due to fast delivery and quick site erection.

- Reduction in project cost: Cost savings primarily result from above time savings on the project. This also results in earlier realization of revenue to owner on a commercial project.

- Large clear spans: Buildings can be supplied in clear spans up to 100 m particularly suitable for warehouses, aircraft hangers, sports facilities, etc.

- Flexibility in expansion: Buildings can be designed for future expansion in length, width and height.

- Superior quality: Excellent Quality can be maintained due to fabrication at plant

- Low Maintenance: High-quality paint systems are available for steel and cladding to provide a long maintenance free service life.

- Energy efficiency: Buildings are supplied with roof and wall insulation to reduce energy costs and improve comfort level inside the building.

- Architectural versatility: Buildings can be supplied with special fascias, canopies, curved eaves and other architectural features required on the project.

- Single source responsibility: As the complete building steel package is supplied from a single source , client is assured of proper interface between all components, resulting in a weather-tight building with good appearance.

PEB VERSUS CONVENTIONAL STEEL BUILDINGS

PEB Conventional

| Design |

Quick and efficient; since PEBs are mainly formed of standard sections and connections, design time is significantly reduced. Basic designs are used over and over. |

Slow: Each conventional steel structure is designed from scratch by the Consultant, with fewer design aids available to the Engineer. |

| Delivery |

Average 6 to 8 weeks. |

Average 20 to 26 weeks. |

| Foundations |

Simple design, easy to construct and light weight. |

Extensive, heavy foundations required. |

| Erection Cost & Time |

Both costs & time of erection are minimized. |

Typically, they are 20% more expensive than PEB. In most of the cases, the erection costs and time are not estimated accurately. |

| The erection process is easy, fast, step by step and with hardly any requirement for equipments. |

Erection is slow and extensive field labor is required. Heavy equipment is often needed. |

| Architecture |

Outstanding architectural design can be achieved at low cost using standard architectural features and interface details. |

Special architectural design and features must be developed for each project, which often require research and thus resulting in much higher costs. |

| Future Expansion |

PEB Building are designed with future expansion in mind. It is simple, easy and cost effective. One supplier can co-ordinate changes. |

Future expansion would be more difficult and, more likely, costlier. |

| Responsibility |

Single responsibility for design, supply and even erection of PEBs. |

Multiple responsibilities can result in questions of who is responsible when components do not fit properly |

Diff between PEB and Conventional

Answer / Solution

In PEB systems, the complete steel building which includes the primary members, secondary members, cladding system, building accessories and other components are delivered to site and erection is carried out fastly as all the building components are fixed through nut and bolt connection. No site fabrication or welding is involved which results in significant savings in construction time and superior quality when compared to conventional steel construction.

The PEB system is highly efficient in design due to synergy between building components. Primary members are made of tapered, built-up sections and secondary members from cold- rolled sections made of high-strength steel. High- strength steel is used. All structural elements are fully optimized by the proprietary computerized design program and hence there is a significant reduction in dead load reactions to the foundations.

Q.1. Is there any saving on civil work / foundation by using PEB

Answer / Solution:-Yes. Because of lesser self weight, we estimate savings to be at least 5%. However if you compare with local method of using fixed bases versus pinned bases in design, the saving would be in excess of 15%.

Q.2. Can we dismantle and shift the structure to other location....

Answer / Solution:-Yes. Since the building is site assembled by bolting, it is possible to dismantle and rebuild at a new location. If the wind speed of the other location is higher we can strength and use it accordingly

Q.3. Is design by American code safer as compared to IS Code

Answer / Solution:- the building is designed by MBMA, AISC codes and are very much safe. In PEB industry major buildings are designed with these codes only unless and until strictly specified.

Q.4.What maximum span can be designed in PEB.

Answer / Solution:-there are no limitation on span of a building. We can design a building of 100m clear span or even more.